Executive summary

Building activity is surging in Gulf Cooperation Council (GCC) countries. This building boom presents an opportunity for the region to pioneer more sustainable construction practices and, in the process, move closer to meeting its net-zero commitments. The key to reaching these goals: ramped-up use in construction of recycled materials, and especially recycled plastics.

Conventional building materials such as steel, cement, and even clay bricks have a large environmental footprint. Manufacturing, transporting, and installing them in construction projects are all carbon intensive. Worldwide, the building materials sector contributed about 10 percent of global greenhouse gas (GHG) emissions in 2019. Reducing that footprint is a priority for the industry—and it is an area in which GCC countries could take the lead.

We examined nine potential applications of recycled plastics in building materials to gauge their environmental and economic impact in the GCC. We estimate that GCC countries alone could cut CO2 emissions by about 2 to 2.5 percent of the expected emissions from the buildings materials sector by 2040. Along with making this positive environmental impact, substituting recycled plastics would encourage innovation, create up to 13,000 jobs, and boost GDP by some US$2 billion to $3 billion by 2040.

All key stakeholders need to take action to increase the use of recycled plastics in construction if they are to have a large environmental impact. They should set up dedicated innovation hubs across GCC countries to drive technological advancements for recycled plastics use in building materials, put in place regulatory standards and targets, and allocate public- and private-sector capital to support investments in the use of recycled plastic— investments and efforts that will help the region meet its sustainability goals, foster innovation, and achieve recognition as a technology pioneer.

Recycled plastics are a viable alternative to traditional, high-emissions building materials

Recycled plastics can help reduce emissions in two ways. First, they can support enhanced recycling and reuse of existing materials—for example, plastic waste can be used as an ingredient to make “green” concrete. Second, recycled plastics can substitute for high-emissions materials such as brick or steel. Use of plastics as a building material has nonetheless taken time to gain acceptance, in part because of a lack of awareness of its suitability for construction, and in part because of misconceptions about its potential hazards and toxicity in the event of fire. The growing track record of plastics usage and improved technology have shown such concerns to be unfounded. In Western Europe, for example, fire fatalities have substantially declined in the past two decades, even as the use of plastics in building and construction has doubled.

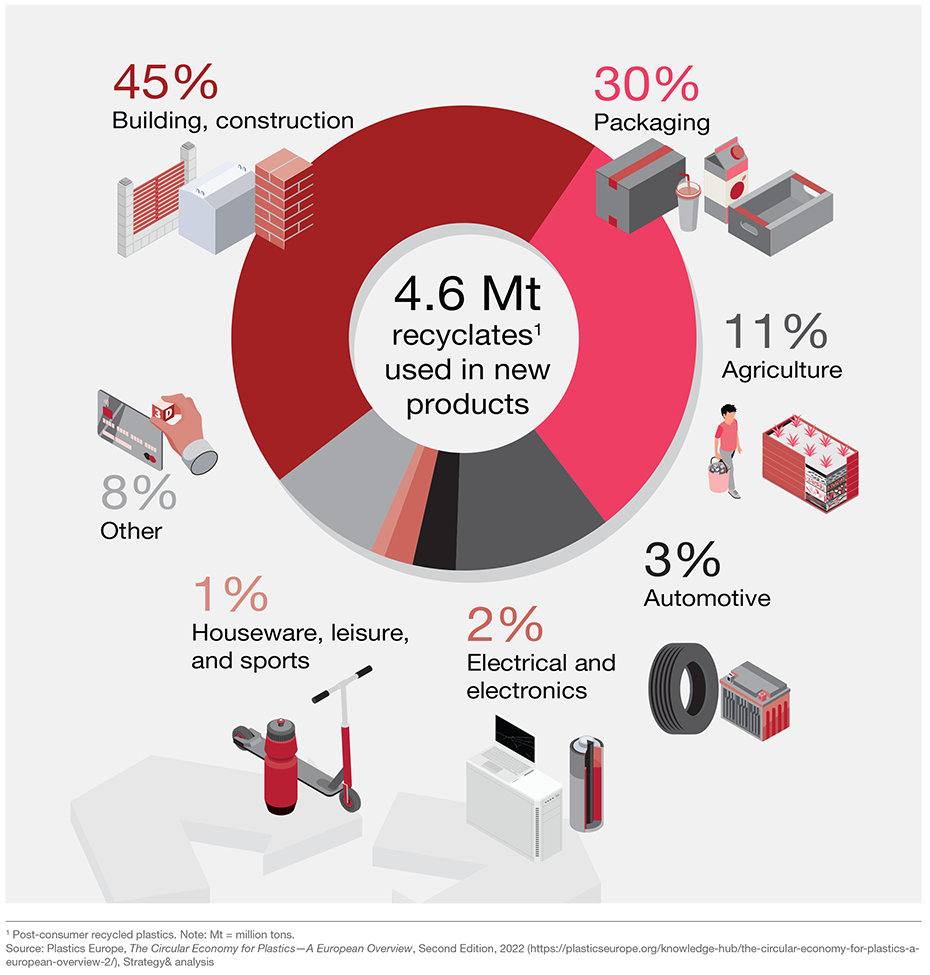

The European experience with recycled plastics in the building and construction sector also underscores the advantages. Plastics are easier to transport, handle, and install than other materials because of their light weight. They preserve their required mechanical properties for use in construction applications. Building materials made of recycled plastics also have a long shelf life and are easier to recycle than mixed plastics and many other materials. Just under half of post-consumer recycled plastic in Europe is now used in building and construction, including for bricks, curbstones, and fences, whereas about one-fourth is reused in packaging.

Europe uses just under half of all post-consumer recycled plastics in building materials

Use of recycled plastics in the E.U., Norway, Switzerland, and the United Kingdom (2020)

More commonly used items, which include concrete, brick, cement, and steel, are also the materials that are responsible for more than 90 percent of the total carbon emissions generated by the building materials sector. Steel and cement each account for about 25 percent of the sector’s carbon emissions on a consolidated basis, brick accounts for 22 percent, and concrete accounts for a further 20 percent. Of these materials, steel is the most significant carbon emitter given its large role in the sector: Manufacturing, transporting, and installing steel, for example, generate GHG emissions of between 2,820 and 6,290 kilograms per ton of CO2 equivalent for every ton of steel. That compares with 370 to 1,800 kilograms per ton of CO2 equivalent emitted in the manufacture of cement.

Conclusion

GCC countries have a significant opportunity to establish themselves as trailblazers at a global level by substantially increasing the use of recycled plastics in building materials. Their substantial spending on construction projects over the next decade and beyond, already earmarked, creates the preconditions for such a move.

Surmounting the challenge of using more sustainable building materials can boost the region’s innovative capabilities and profile—and could enable GCC countries to largely define and set global standards on the use of recycled plastics. At a time when all countries are looking for ways to reduce GHG emissions, the large-scale deployment of recycled plastics can help GCC countries move faster to net-zero emissions, and build a better future for their economies and the planet.

Contact us

Menu