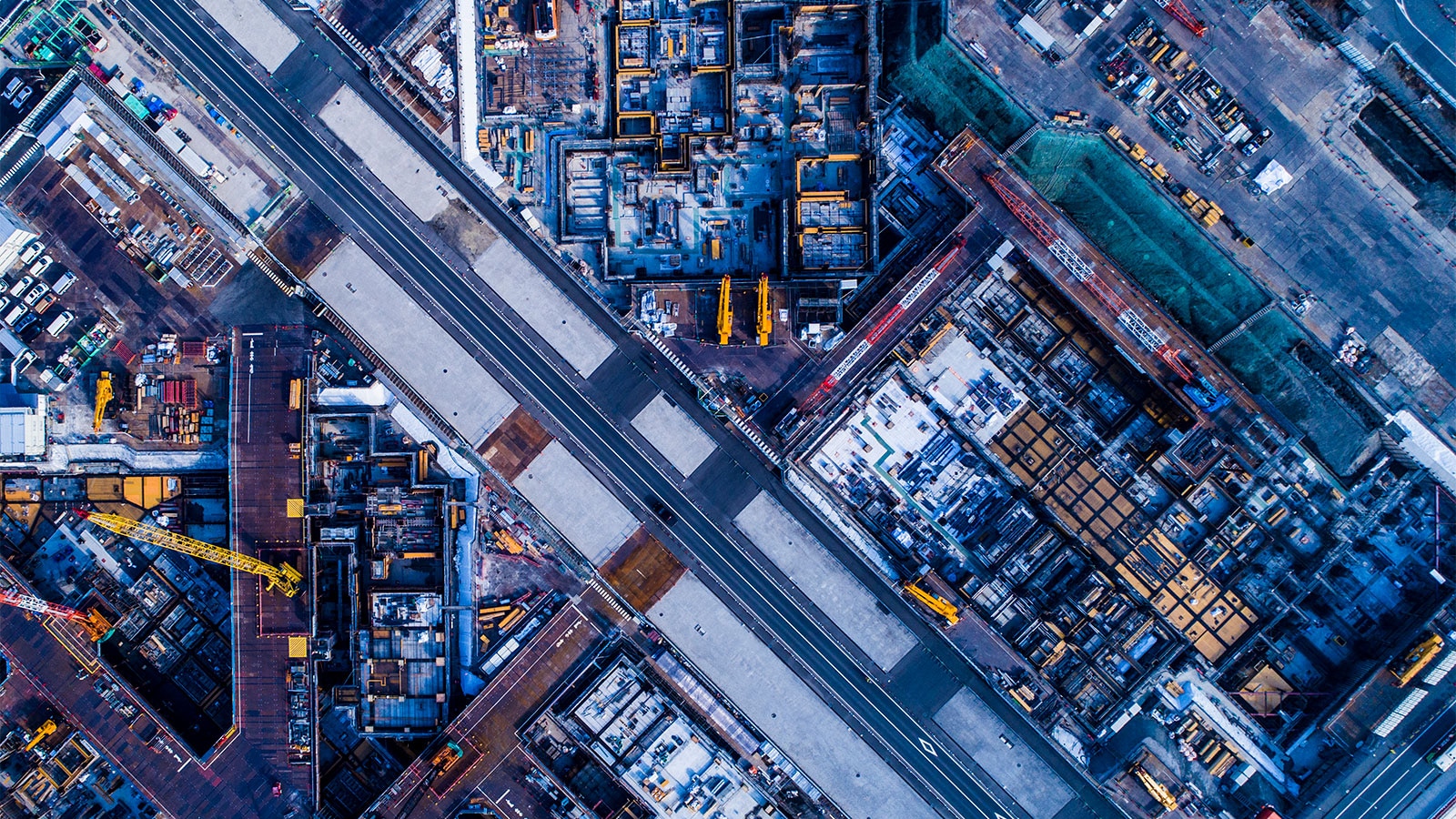

The GCC’s building and construction industry is on the brink of a transformation that could be felt globally. For the past 30 years, GCC governments have successfully used mega programs to diversify and expand their economies. From creating industrial port cities such as Yanbu and Jubail in Saudi Arabia, to building downtown Dubai with the Burj Khalifa as its beacon, mega programs have created landmark places to live, work, and visit.

As of early 2020, there were close to 30 mega programs in the pipeline that should become largely operational over the next decade. With around $1 trillion in investment, they represent close to half of the region’s $2.3 trillion construction pipeline. They range from urban regeneration programs to large-scale smart cities.

Mega programs are complex. They magnify the challenges inherent in building and construction: a fragmented and non-localized value chain, limited use of digital tools and technology, an insufficiently skilled workforce, lack of adequate planning, complex governance, and sometimes archaic regulations. The fragility of the economic climate could limit government funding for mega programs and reduce tolerance for time and cost overruns.

Indeed, the toll of a mega program’s failure is greater than of a standard construction project. Achieving visionary feats requires discipline. GCC countries therefore should take full advantage of the long-overdue, ongoing, building and construction transformation that involves industrialization, professionalization, digitization, and consolidation. Changes that took other industries several decades could occur in GCC building and construction in under a decade, providing an opportunity for GCC countries to become leaders in mega programs

Owners, investors, regulators, and suppliers need eight priorities.

-

It is vital at the outset to develop a clear mega program strategy.

It should decide whether the approach is self-development, private sector partnership, or a combination. Self-development requires the most efficient design-build model. All cases require conscious choices about the project management and design model (e.g., modular versus traditional), which in turn affects building material choices, the difficulty of construction, and how the mega program will operate.

-

Mega programs should use “industrialized” construction and next-generation materials.

There is a shift from labor-intensive methods to construction that is prefabricated and “productized” (breaking down a building into components and sub-components). Incorporating cutting-edge materials early in the design phase can enhance economies of scale thanks to durability, performance, cost, and environmental sustainability.

-

Mega programs should source inputs strategically and resiliently.

Centralized, coordinated, and holistic sourcing across a mega program can provide greater value and supply chain security, particularly when managing supply disruptions and constraints. Increased localization of construction materials supply chains makes sourcing more efficient and robust. That contrasts with the practice until now of scoping and executing procurement on a project-specific basis, with a preference for the lowest price to the detriment of quality, durability, and ecological merit.

-

There should be fit-for-purpose mega program governance and operating model.

These are essential for project delivery with appropriate checks and balances, but without unnecessary bureaucracy. That requires a uniform stage gate process (program lifecycle), governance committees, delivery operating organization and operating model, a set of standards and procedures, and talent management.

-

Mega programs need in-house centers of excellence to share knowledge and experience effectively, while enforcing compliance with technical standards.

Centers of excellence define policies and procedures, set standards and material specifications, research and adopt latest trends. They identify innovations in engineering and construction, promote their adoption, manage supplier relations, and develop talent.

-

Mega programs should pursue digitization from their inception.

Digitization allows for transparent, data-driven, real-time, and efficient decision-making. For example, Building Information Modelling creates a 3D version of a development that project owners can manipulate to understand possible construction problems.

-

Mega programs need the right talent.

Project owners can think about job families: white collar positions (for example, project management, project controls, and engineering) are in demand, requiring effort to hire talent. Blue collar positions are changing because of the move to industrialized construction, requiring manufacturing assembly line workers rather than unskilled labor.

-

Environmental, social, and governance (ESG) standards can enhance livability.

ESG concerns should be intrinsic to mega program development, not secondary. That means deliberate trade-offs about cost, time, quality of asset, quality of life, and asset usability. Developments are now showcasing such distinguishing features as access to green spaces, micro-mobility solutions, live-work-play proximity, and carbon neutrality. Mega programs can achieve such outcomes if they incorporate ESG requirements at the design and development phase.

These eight priorities cannot only support delivering mega programs on time and on budget, but also ensure delivery of high-quality assets that are designed around human wellbeing and environmental sustainability resulting in a better quality of life. They can also create leading-edge construction supply chains, capability systems, and delivery disciplines that put GCC countries in the forefront of global mega program development.

This article originally appeared in Construction Business ME, September 2023.

Contact us

Menu