The traditional and dominant linear economic model of “take, make, use, and waste” is unsustainable. The linear model is not only wasteful but also environmentally damaging. Regulators and customers want an end to the linear model and are demanding environmentally friendly practices and products. The linear model’s successor is the circular economy model (CE), which seeks to reuse products and treats waste as a loss of value. Companies are adopting the CE as it can lead to competitive advantage, offers a response to customers, and is less damaging to the environment. The CE can lower operating costs and create new products and services that facilitate incremental value creation and sustained growth.

Opportunities for chemicals companies

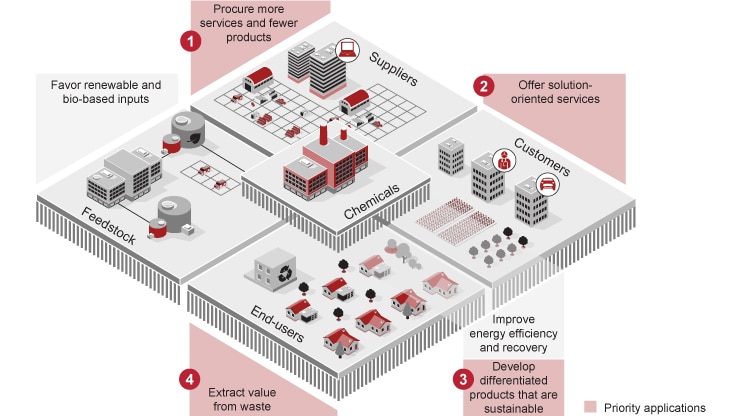

The CE is particularly important for chemicals companies, which can adopt four priority applications for competitive advantage: circular procurement, customer value chain integration, circular products, and end-product recycling.

High-impact circular applications can be adopted in the chemicals industry

Off the road: A new life for used tires

Tire recycling presents a promising opportunity for chemicals companies in the GCC region. Reclaimed or recycled rubber can substitute for natural or synthetic rubber in the energy, water, and automotive sectors. Watch the video to learn more.

Advancing the CE agenda internally

Chemicals companies should begin by deciding their commercial rationale for moving to the CE. Once they define the business objectives, they can consider pilot projects that are likely to reap short-term rewards and inspire the confidence to continue within the organization. They also need to change their corporate culture so that the CE becomes second nature to their staff.

A circular transition relies on internal transformation starting with a solid strategy and objectives

Contact us

Menu