When planning their future production system strategy, OEMs and suppliers will have to shift their focus. ESG has become a major driver for planning, decisions, and investments. The ESG+ Impact Metrics analyzes all variables and provides sustainable guidance and solutions for COOs and plant managers towards the design of a net zero production system.

Transparency, pressure, and design

ESG changes the game for players in the automotive industry, aerospace, and manufacturing

“ESG” has evolved from a buzzword into a profound transformation of entire industries. The impact especially on suppliers and OEMs is huge as requirements regarding ESG criteria are becoming more challenging and complex, presenting COOs with major challenges like rising costs along the planning- and production circle. But what are the increasing external ESG drivers? For one, there is a demand for higher transparency on social responsibility along the supply chain. Also, regulations are becoming stricter and more complex: Besides new product eco-design requirements, KPI systems are being recalibrated to ESG topics. Another strong driver is the net zero pathway and the goal of a decarbonization of the full product lifecycle and supply chain. Further, there is a booming demand for ESG investment classes and a corresponding need for quantified ESG impact. This brings the supply chain strongly into focus, too: they are being further glocalized to mitigate ESG-risks. Finally, COOs must balance these comprehensive requirements against avoiding high costs later, as failure to meet the requirements can cost the company much more. Therefore, it is important for OEMs, their suppliers, and investors to focus on their production system and design phase when considering ESG, as this is where the company's ESG impact is greatest and where the future footprint (environmentally and financially) is decided.

Strategy& has taken a 360-degree look at relevant data and developed a practical ESG+ Impact Metrics as a skilled methodology for COOs and plant managers in the automotive, aerospace or manufacturing industries to make the right, sustainable decisions for their business.

Taking a leap in planning and designing production system for ESG

In a production system the biggest ESG impact is made during the planning and design phase.

When aiming for a higher ESG performance, it is particularly this phase that is relevant, because this is where the course for the operative phase is set. This means that the highest impact can be achieved early on, proving it to be cheaper to plan right in the beginning, than to fix deficiencies afterwards, e. g. concerning the energy requirements of future factory operations. Therefore, it is vital to consider ESG in the beginning, when setting up the system to be able to improve ESG performance and avoid later high costs.

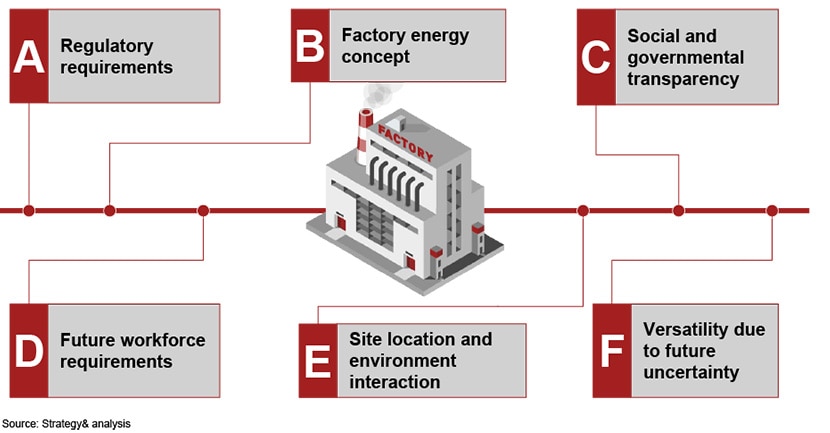

The impact of today’s decisions poses the main challenge when designing a production system

There are several strategic challenges COOs or plant managers face during the design and decision phase of a net zero production system – from regulatory requirements to the factory energy concept, to social and governmental transparency, to the future of workforce requirements, to site location and environment interaction, or to versatility due to future uncertainty.

The core challenge is the impact of these decisions: what is being agreed on today will impact the total factory life span. Especially when planning upfront, a big challenge remains the uncertainty of the future. There are, for example, many EU regulations currently under development (examples to be named: “Fit for 55”, “Hydrogen directive”, “Human rights”, “Eco-Design”), which makes it difficult, but at the same time necessary, to anticipate potential future regulations now. Thus, a solution is required that enables companies to assess ESG early on by integrating regulations and potential future developments.

How to get a structured ESG+ evaluation of different production system options

Our ESG+ Impact Metrics provides support with the help of a tool supported methodology to be used during the entire production system development process. The method includes all ESG+ dimensions such as environment, social, governance, economy, and resilience to make them measurable and steerable throughout all milestones. In practice, the evaluation of these happens in two steps:

Firstly, decisions per production system milestone can be evaluated against each other considering all ESG+ dimensions. This helps to decide which option to choose, for example “Do I transport parts via truck or via train?”. With our method and tool, we can assess the variable in detail and provide an answer to the question “What in the dimensions of ESG+ will be the best possible option for the future production system?”.

Secondly, a structured ESG+ evaluation can be accomplished by choosing options per element with which the ESG+ performance can be steered along all milestones. This means that in the design phase we can track and steer e. g. the estimated CO2 footprint of the production system based on the selected options: In case you would have chosen a truck instead of a train for material transport, the CO2 consumption of the overall system would have been higher by a certain percentage.

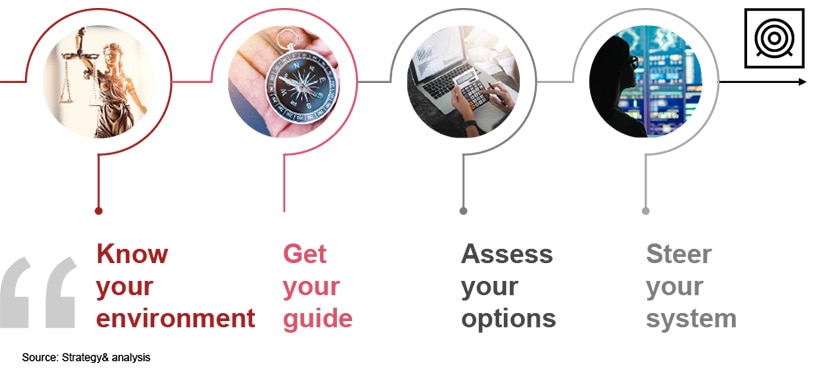

Set up and tailor made in four steps

ESG+ Impact Metrics for a company’s specific needs

Our expert team has thoroughly developed the process and developed a four-step approach to set up and use the ESG+ Impact Metrics.

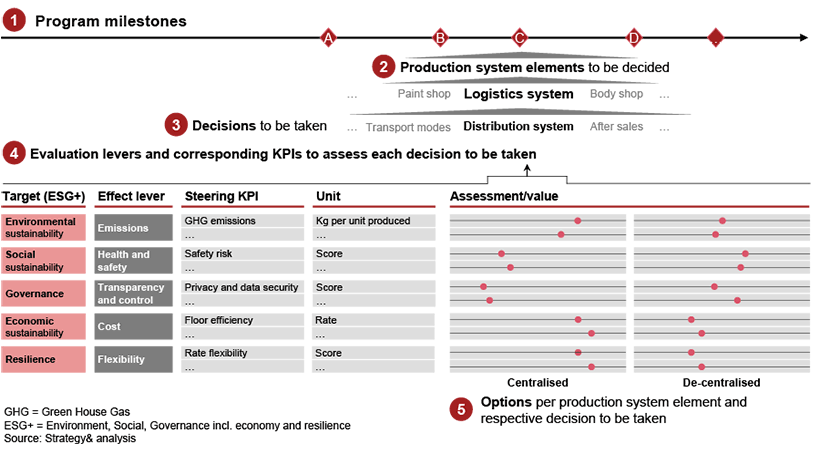

Providing decision support along the developed approach

But how do the set up and the different hierarchies of the developed method work? During the development phase there are typically different milestones. At each milestone, different elements need to be finally decided by you (e. g. do we transport via truck or via train) so that, based on that decision, the production system can be further designed.

Then, the specific elements of the production system need to be decided on, like having a distribution system centralized or de-centralized. These decisions must then be thoroughly assessed, in close collaboration with our team of advisors.

At the heart of the method are the five target dimensions (environmental, social, governance, economic, resilience). For each of these, we have different effect levers (emissions, health and safety, transparency and control, cost, and flexibility) that describe how for instance an environmental sustainability of a distribution system can be measured. The effect lever “emissions” would measure e. g. Green House Gas and the kg per unit produced. Finally, you then have KPIs for each lever with different units, with which results can be quantified and calculated. This structure and process shows that after entering and computing all data, the system offers various options including which would be the best option to choose based on the different decisions for each dimension. It might be, after all, that one of the options is the best for environmental sustainability, but the other option is much better regarding economic sustainability.

In a nutshell

Four success factors to set up your ESG+ Impact Metrics

For COOs and plant managers of OEMs or suppliers, a thorough set up of the ESG+ Impact Metrics for their production system can be decisive. But to use the ESG+ Impact Metrics successfully, the following four factors need to be considered.

- 1It is of great importance to monitor regulations due to changes

- 2The creation of stakeholder buy-in from other teams and divisions enables an integration of existing standards in the development and catalyzes the future use of the system

- 3Also, an ESG+ target break-down for each element along all milestones enables the steering of the production system with the ESG+ Impact Metrics from the beginning

- 4Finally, to plan a sustainable production system for the future, OEMs and suppliers need to systematically and quantifiably assess their ESG+ targets

The ESG+ Impact Metrics by Strategy& helps to balance effect levers and steer KPIs, and to make seemingly abstract decisions for plants that yet must be built. However, only those who plan today for tomorrow can ensure the best company results in the future.

Anna Paulina Went, Tim Joussen and Leon Rupp also contributed to this article.